What is soft sensation yarn and what are its functional characteristics?

What is soft sensation yarn?

Soft sensation yarn is a type of yarn with special softness and comfort, which is usually used to enhance the touch and wearing comfort of textiles. soft sensation yarn uses raw materials or textile processes that are different from traditional yarns. It can make the fabric softer and smoother while retaining the strength and durability of the yarn itself, bringing a better skin feel experience.

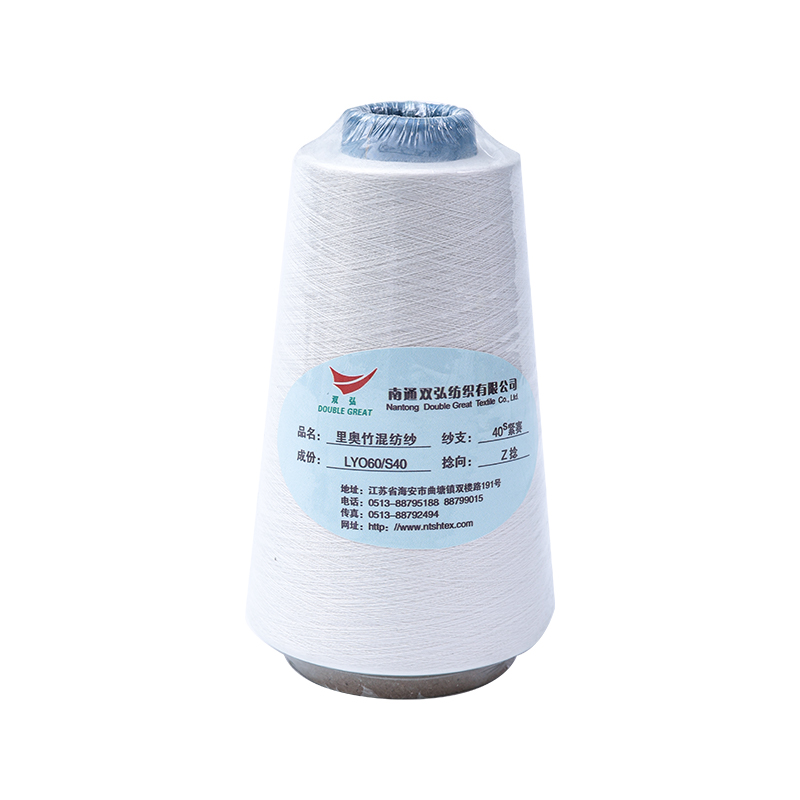

In the production process of Nantong Double Great Textile Co., Ltd., the manufacture of soft sensation yarn involves sophisticated textile technology and high-quality raw materials. The company uses natural and synthetic fibers including cotton, polyester, acrylic, and environmentally friendly viscose, which can provide soft sensation yarn with a soft touch and excellent wearing experience. In addition, Nantong Double Great Textile Co., Ltd. also ensures that the production process of soft sensation yarn reaches a high precision by introducing advanced production equipment, such as precision combing machines, long spinning machines and automatic winding machines from Switzerland, Germany and Japan, thereby effectively improving the quality and touch of the yarn.

Production process of soft sensation yarn

The production process of soft sensation yarn has an important impact on its final touch and quality. Nantong Double Great Textile Co., Ltd. uses advanced textile technology to ensure the high quality of soft sensation yarn. For example, during the spinning process, the combing process can remove impurities in the fiber and optimize the arrangement of the fiber, making the yarn smoother and more delicate. In addition, the use of long spinning machines also makes the twist of the yarn more uniform, thereby improving the softness of the yarn.

The company also uses some innovative technologies in the production process, such as special fiber treatment and blending process, to achieve the purpose of enhancing the soft effect of the yarn. Through these advanced production processes, Nantong Double Great Textile Co., Ltd. can ensure that its soft sensation yarn meets high standards in touch and meets consumers' needs for comfort and quality.

Functional characteristics of soft sensation yarn

In addition to the soft touch, soft sensation yarn also has some other functional characteristics, which makes it highly competitive in the market. Nantong Double Great Textile Co., Ltd.'s soft sensation yarn not only focuses on the softness of the yarn, but also optimizes and innovates in the following aspects:

Moisture absorption and perspiration function

Many soft sensation yarns use fiber materials that can effectively absorb moisture and perspiration, which allows the fabric to stay dry during wear. This moisture absorption and perspiration function is especially important for summer clothing, which can help reduce the accumulation of sweat and avoid skin discomfort. Fibers such as polyester and acrylic used in soft sensation yarns have good moisture absorption and perspiration properties, which can quickly absorb sweat from the skin and evaporate it quickly, thereby improving the comfort of wearing.

Antibacterial function

Another important feature of soft sensation yarns is antibacterial properties. Antibacterial yarns can inhibit the growth of bacteria and other microorganisms in daily wear, thereby reducing the generation of odors and protecting the skin from infection. Nantong Double Great Textile Co., Ltd. incorporates antibacterial technology into some soft sensation yarns, making its yarns not only soft, but also effectively improving the hygiene of the fabric.

Good breathability

soft sensation yarns usually have good breathability, which can effectively regulate the temperature and humidity inside the fabric and maintain comfort. Yarns with good breathability can allow air to circulate, avoiding stuffiness and airtightness when wearing, especially in hot weather, which can enhance the wearing experience.

Environmental protection function

As consumers' awareness of environmental protection increases, environmental protection has become an important feature of many textiles. Nantong Double Great Textile Co., Ltd. incorporates the concept of sustainable development into the production of soft sensation yarns, using environmentally friendly materials such as recycled polyester and environmentally friendly viscose to reduce the consumption of natural resources and reduce environmental pollution. These environmentally friendly yarns not only maintain softness and comfort, but also meet the needs of modern people for sustainable products.

Market application of soft sensation yarns

soft sensation yarns are widely used in many fields due to their excellent comfort and multiple functional characteristics. Especially in the clothing industry, soft sensation yarns have become one of the preferred materials for high-end fashion brands. Nantong Double Great Textile Co., Ltd.'s soft sensation yarn has been adopted by international fashion brands such as LV, H&M, Adidas, and Unlo as their supplier.

In addition to its application in the clothing field, soft sensation yarn has also shown broad market potential in home textiles, sporting goods and other fields. The moisture absorption and perspiration, antibacterial and breathable properties of soft sensation yarn make it widely used in sportswear and sports equipment. For example, soft sensation yarn can be used in sportswear, running shoes, sports socks, etc. to improve the comfort and performance of wearing.

Quality control of soft sensation yarn

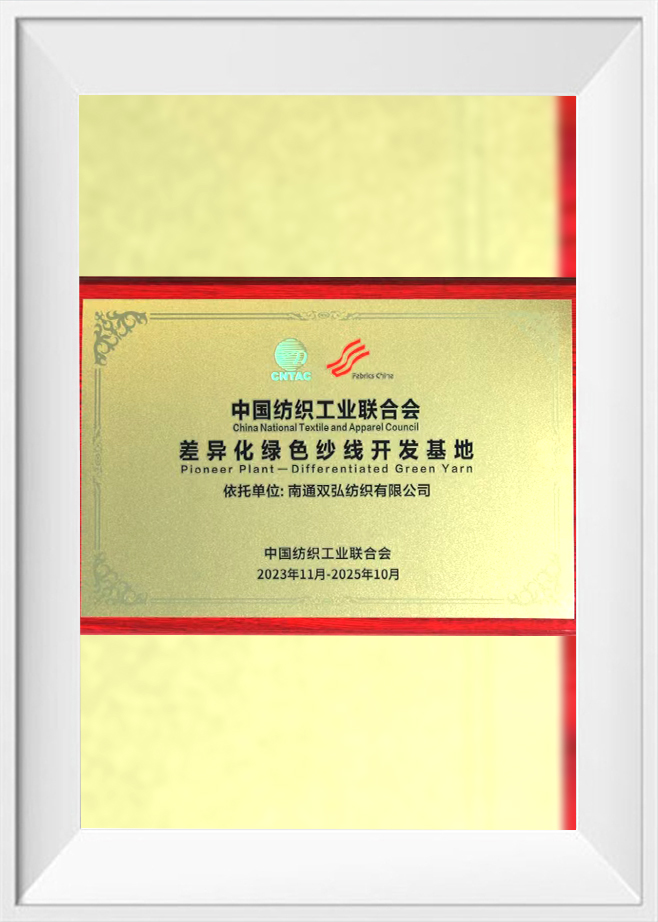

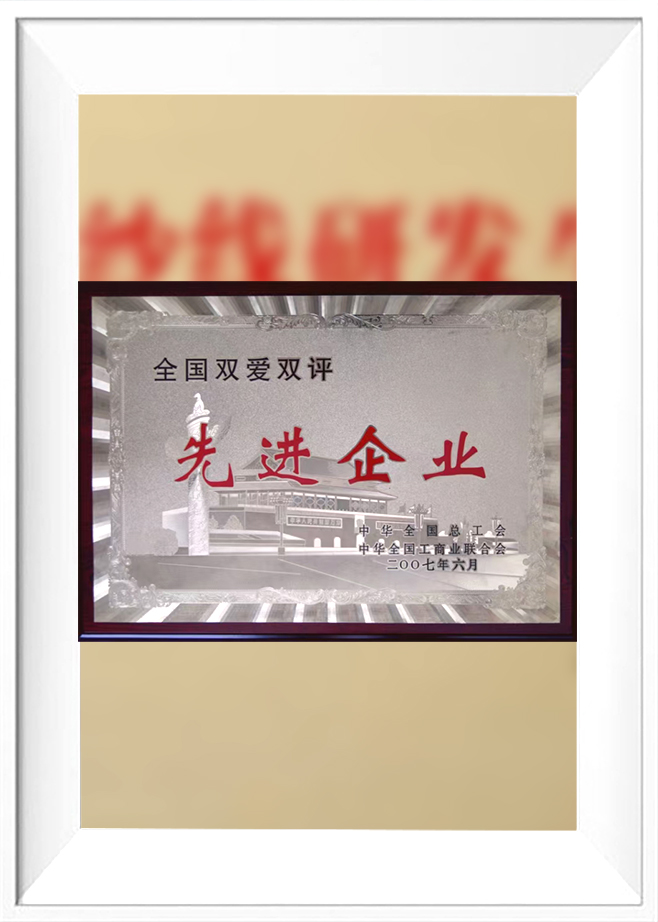

As an industry-leading enterprise, Nantong Double Great Textile Co., Ltd. pays attention to quality control in the production of soft sensation yarn. The company has advanced quality testing equipment and experimental platforms, such as USTER testing equipment, which can accurately test each batch of yarn to ensure its quality stability and consistency. In addition, the company has passed the USTERIZED quality system certification and obtained CNAS accreditation, and has the industry's authoritative quality certification. These quality control measures provide a strong quality guarantee for the company's soft sensation yarn.

How environmentally friendly is soft sensation yarn and how is it different from ordinary yarn?

How environmentally friendly is soft sensation yarn?

Soft sensation yarn has been widely used in the modern textile industry, and one of its key features is its environmental friendliness. With the improvement of environmental awareness and the popularization of the concept of sustainable development, more and more textile companies have begun to pay attention to the use of environmentally friendly materials and process improvements in the production process. Nantong Double Great Textile Co., Ltd. fully considered this factor when producing soft sensation yarn and adopted a series of environmental protection measures.

Use of environmentally friendly raw materials

The environmental friendliness of soft sensation yarn is first reflected in the raw materials it uses. Nantong Double Great Textile Co., Ltd. actively promotes the use of recycled fibers and degradable fibers to reduce the burden on the environment. For example, the company widely uses recycled polyester, environmentally friendly viscose and other raw materials in the production of soft sensation yarn. These materials come from recycled waste textiles or plastic bottles, etc., and are processed by advanced technology to be remade into fibers, which not only reduces resource waste but also reduces pollution to the environment.

Nantong Double Great Textile Co., Ltd. also actively develops and applies degradable fibers such as PLA (polylactic acid), which can naturally degrade after the end of their service life, avoiding the long-term pollution of the environment caused by traditional plastics and textiles. By adopting these environmentally friendly raw materials, the production of soft sensation yarn not only meets the market demand for environmental protection, but also promotes the sustainable development of the textile industry to a certain extent.

Green production process

In addition to the selection of raw materials, the production process also plays an important role in the environmental protection of soft sensation yarn. In the process of producing soft sensation yarn, Nantong Double Great Textile Co., Ltd. strictly controls each link to minimize energy consumption and waste emissions. The company has introduced advanced production equipment and technology to ensure efficient resource utilization and energy conservation in the textile process. For example, in the dyeing and finishing process, the company uses environmentally friendly dyes and auxiliaries to reduce the use and emission of harmful substances and ensure that the products meet international environmental standards.

Environmental certification and testing

Nantong Double Great Textile Co., Ltd.'s soft sensation yarn has passed a number of environmental certifications to ensure that the product meets environmental requirements in all links. The raw materials and production processes used by the company have been strictly tested and certified, and meet the ISO14001 environmental management system certification and other relevant green certification standards. Through these certifications, the company's soft sensation yarn not only meets the industry standards in terms of environmental protection, but also ensures the stability and consistency of product quality.

Differences between soft sensation yarn and ordinary yarn

Soft sensation yarn has some significant differences compared with ordinary yarn. It is mainly reflected in the touch, comfort, functionality and environmental protection of the yarn. Nantong Double Great Textile Co., Ltd. combines market demand and consumer preferences in the research and development and production of yarns to develop soft sensation yarns with unique advantages.

Touch and comfort

Ordinary yarns are usually made of natural or synthetic fibers, which may feel rough and may cause friction discomfort when worn. In contrast, soft sensation yarns add soft materials or use special processes during the weaving process, which can significantly improve the softness and comfort of the yarn. This soft touch makes soft sensation yarns widely used in high-end clothing, home textiles and other fields, especially for consumers who have high requirements for comfort.

For example, Nantong Double Great Textile Co., Ltd. uses high-quality cotton and other soft fibers, and through combing and long spinning processes, the surface of the soft sensation yarn is smoother, softer to the touch, and more comfortable to wear. Ordinary yarns have not undergone this special treatment, and their touch and comfort are relatively poor.

Moisture absorption and perspiration and breathability

Another feature of soft sensation yarn is its good moisture absorption and perspiration function. Ordinary yarns are generally limited in moisture absorption and breathability, especially when worn in summer, which easily leads to moisture accumulation and affects wearing comfort. soft sensation yarns can effectively absorb sweat from the skin and evaporate it quickly to keep the skin dry by using fibers with moisture absorption and perspiration function.

Nantong Double Great Textile Co., Ltd.'s soft sensation yarns pay special attention to breathability. The fibers used, such as polyester and acrylic, have good breathability, allowing air to circulate freely, thereby improving the comfort and functionality of the fabric. Ordinary yarns may not achieve this breathability and moisture absorption effect due to the high fiber density or processing technology limitations.

Environmental protection comparison

In terms of environmental protection, there are also significant differences between soft sensation yarn and ordinary yarn. Ordinary yarn often uses traditional synthetic fibers or dyes, which may generate more waste and pollutants during the production process. In contrast, the soft sensation yarn of Nantong Double Great Textile Co., Ltd. uses environmentally friendly raw materials (such as recycled polyester, PLA, etc.) and green production processes to greatly reduce the impact on the environment during the production process.

The dyes and auxiliaries used in the production process of soft sensation yarn are also strictly screened environmentally friendly products, which reduces pollution to the environment. Compared with ordinary yarn, this has a stronger environmental advantage.

Combination of functional yarns

Soft sensation yarn can also be combined with other functional yarns to improve the performance of the yarn. For example, the soft sensation yarn produced by Nantong Double Great Textile Co., Ltd. can be combined with functional fibers such as Coolmax and antibacterial, so that the yarn not only maintains a soft touch, but also has antibacterial, moisture absorption and perspiration functions. This kind of composite functional soft sensation yarn is suitable for sportswear, underwear and other fields that require high comfort and functionality. Ordinary yarn generally does not have such versatility, but focuses more on basic structure and durability.

English

English русский

русский Español

Español