What is the difference between polyester blended yarn and pure polyester yarn?

Differences in raw material structure

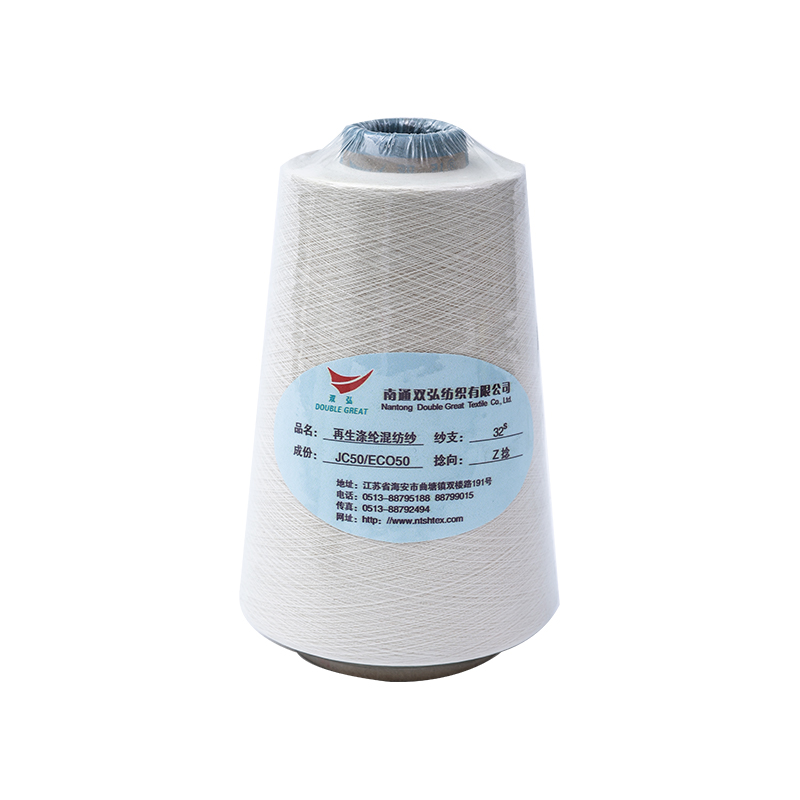

Pure polyester yarn is made of 100% polyester fiber and is a fully synthetic fiber yarn. Polyester blended yarn is made by mixing polyester with other fibers in a certain proportion. Common blended ingredients include cotton, viscose, acrylic, modal, PLA, etc. Nantong Double Great Textile Co., Ltd. has many years of experience in blended yarns and is good at combining a variety of environmentally friendly and functional fibers, such as recycled polyester and eco-viscose blends, polyester and ramie blends, etc.

Different yarn performance

Due to differences in raw material composition, pure polyester yarn usually has higher strength, elastic recovery and abrasion resistance, but lower hygroscopicity. In contrast, polyester blended yarn can show better comprehensive performance according to the type of blended fiber. For example, polyester-cotton blended yarn has better hygroscopicity and breathability, while polyester-viscose blended yarn is softer and helps improve wearing comfort. This diversified performance adjustment makes polyester blended yarn more adaptable in the fields of clothing, home textiles, and functional fabrics.

The difference between appearance and feel is obvious

Pure polyester yarn is made of synthetic fiber, so its yarn has a strong gloss, a slippery touch, and is prone to static electricity. Polyester blended yarn can improve these characteristics by combining with natural or regenerated fibers. For example, blending with cotton can make the yarn more skin-friendly and more natural to the touch; blending with acrylic can make the fabric more fluffy and warm. Nantong Double Great Textile has strong development capabilities in this area and can achieve different styles of yarn effects through proportion control to meet different weaving purposes.

Dyeing performance and color performance

Due to its stable molecular structure, polyester usually requires high temperature and high pressure dyeing, which is difficult to dye. Pure polyester yarn has a long-lasting color after dyeing, but the color variety and saturation are limited. Polyester blended yarn contains easy-to-dye ingredients, such as viscose, cotton, modal, etc., which makes the color performance richer and can adopt a variety of dyeing processes. Through scientific proportioning, blended yarn can achieve a balance between color saturation and fastness to meet the needs of diversified fabric design.

Different breadth of application fields

Pure polyester yarn is mainly used in industrial fabrics, bags, wear-resistant fabrics, outdoor functional fabrics and other fields, focusing on its strength and durability. Polyester blended yarn is more flexible in clothing, knitting, household goods, functional textiles and other fields due to its adjustable performance. Nantong Double Great Textile Co., Ltd. has widely used polyester blended yarn in functional knitted fabric development projects, such as moisture absorption and quick drying, antibacterial, UV protection and other functional fabrics.

Sustainable development and environmental protection value

As green textiles become the development trend of the industry, polyester blended yarn has shown certain advantages in sustainability. If pure polyester yarn is made of non-recycled materials, it will face greater challenges in environmental degradation. Polyester blended yarn can reduce the environmental burden by combining recycled polyester with renewable fibers (such as PLA, eco-viscose, etc.). Nantong Double Great Textile is actively deploying in this direction, and its blended yarn products use a large amount of green and environmentally friendly raw materials to meet the requirements of the international market for sustainable supply chains.

Cost and processability considerations

Pure polyester yarn has a relatively favorable overall cost control due to its stable raw material source and mature processing flow. It has a fast yarn-forming speed and is suitable for large-scale production. However, polyester blended yarn has high blending ratio and spinning technology requirements, and the processing process requires precise control and the process is relatively complex. Although the cost is slightly higher, the overall performance improvement can be used for high value-added products. Nantong Double Great Textile has a multi-line parallel spinning system, has the ability to produce blended yarns on a large scale and stably, and can provide customized solutions according to different customer needs.

Market positioning matches customer needs

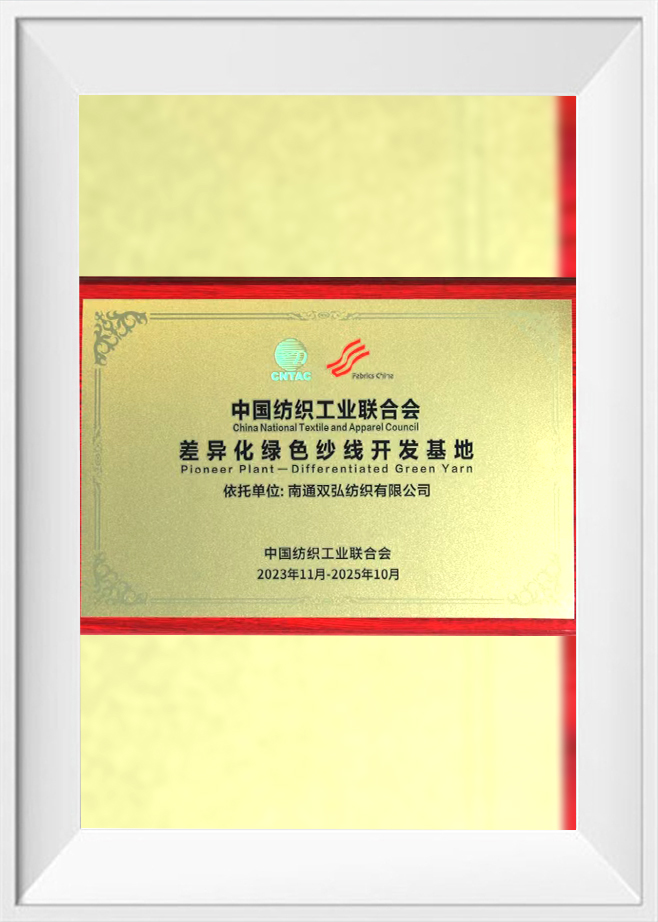

Pure polyester yarn is often used in application scenarios that focus on functionality and cost control, while polyester blended yarn focuses more on comfort, multi-function and design freedom. According to market feedback, different end users have great differences in their expectations for yarn performance. As a national high-quality chemical fiber blended yarn production base, Nantong Double Great Textile Co., Ltd. continues to deepen its research and development of polyester blended yarns, and can provide product selection suggestions based on customer industry attributes, so as to be closer to the performance requirements of end products.

What are the main performance characteristics and uses of polyester blended yarn

Diverse raw material combinations form the basis of performance

The performance of polyester blended yarn is closely related to the blended raw materials used. The blended yarns developed by Nantong Double Great Textile Co., Ltd. include cotton, acrylic, environmentally friendly viscose, recycled modal, PLA, bio-based fibers and other ingredients. Through the deployment of different ratios, the combination optimization of hygroscopicity, softness, elasticity, strength, wrinkle resistance and other aspects can be achieved. The performance of this yarn is no longer solely dependent on polyester itself, but takes into account the advantages of multiple fibers to adapt to more complex weaving and wearing needs.

Stable structure, relatively high wrinkle resistance and strength

As a synthetic fiber with high molecular structure stability, polyester blended yarn has strong structural stability and is not easy to break or deform. In the blending process, this characteristic is partially retained, so that the polyester blended yarn maintains a good physical state during production, transportation and weaving. In addition, the tensile and wear resistance of polyester also improves the service life of the yarn, which is particularly suitable for fabric products with high strength requirements.

Improved hygroscopicity and breathability

Polyester itself has weak hygroscopicity, and it is easy to cause stuffiness and airtightness during wearing. By blending with hydrophilic fibers such as cotton, viscose, and modal, the overall hygroscopicity and breathability of the yarn can be effectively improved. For example, polyester-cotton blended yarn combines the strength of polyester and the skin-friendliness of cotton, and is suitable for regular clothing in all seasons; polyester-viscose blended yarn is more supple and more suitable for underwear. This performance adjustment makes the blended yarn more suitable for daily wear needs.

Improved feel and more skin-friendly touch

Pure polyester yarn often appears to be hard and slippery in touch. The addition of natural fibers to polyester blended yarn makes the yarn feel softer. For example, blending polyester with acrylic can enhance the fluffiness of the yarn; blending polyester with modal brings a smooth and drapey touch. These changes in feel enable the yarn to be better used in intimate fabrics or high-demand home textiles.

Color adaptability and dyeing diversity

Polyester yarn usually requires high temperature and high pressure dyeing, which has high requirements for dyeing equipment and process. Natural or regenerated fiber components in blended yarns, such as cotton and viscose, have good dye affinity. This allows polyester blended yarns to use a variety of dyes and technologies in the dyeing and finishing process, with richer colors and more natural colors. Especially in terms of color matching and printing pattern diversification, blended yarns have higher process compatibility.

Widely used in knitted and woven products

Polyester blended yarns are widely used in knitted fabrics, woven fabrics, sportswear, school uniforms, bedding, underwear, socks, decorative fabrics and other fields. Nantong Double Great Textile Co., Ltd.'s R&D capabilities in this area can cover multiple application levels. For example, the company blends polyester with PLA or ECDP for functional knitted fabrics, which not only ensures the durability of the fabric, but also enhances sustainability, in line with the current green consumption trend.

Suitable for functional textile development

In the field of functional yarns, polyester blended yarns also play an active role. The company can use functional ingredients such as nylon graphene, Coolmax, and Coolvisinos to composite spinning with polyester to develop functional products such as moisture absorption and quick drying, antibacterial, far infrared, and cool feeling. This composite yarn not only enhances the additional functions of the fabric, but is also suitable for professional application scenarios such as sports, outdoor, and protection.

Conducive to sustainable development and environmentally friendly production

Nantong Double Great Textile Co., Ltd. focuses on sustainable development and widely uses recycled polyester, bio-based materials, and environmentally friendly viscose in polyester blended yarn products. This not only reduces dependence on traditional chemical fiber resources, but also reduces carbon emissions and water consumption in the textile process. At the same time, blended products using environmentally friendly fibers are more likely to meet the environmental standards of the international market and improve export compliance.

Balance between cost control and product diversity

The production cost of polyester blended yarn is usually more controllable than that of pure natural yarn, and by flexibly adjusting the blending ratio, it can adapt to the needs of products with different positioning. Whether it is to provide basic fabrics for the mass consumer market or functional or differentiated fabrics for the mid-to-high-end market, blended yarns have adaptability. The company has accumulated a variety of blending ratio schemes in long-term practice and can provide reasonable suggestions based on customer needs.

English

English русский

русский Español

Español