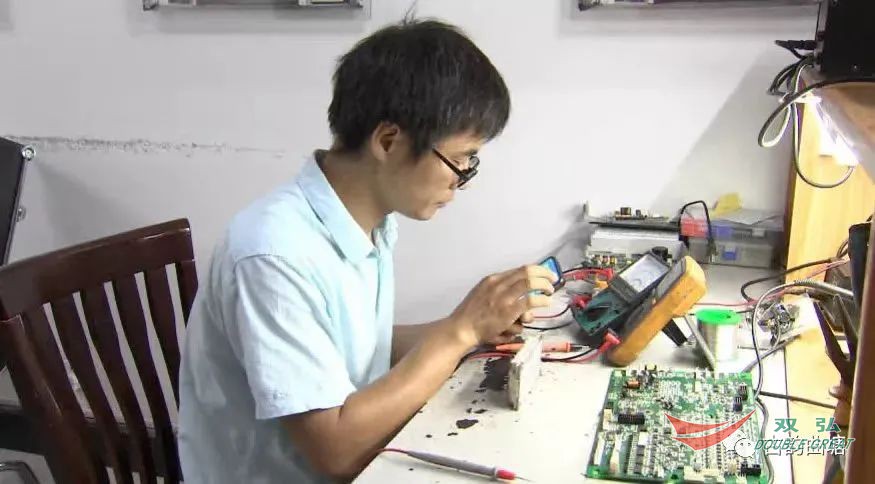

On September 13 , in the skill master studio of Nantong Double Great Textile Co., Ltd., Zhang Yong was repairing a grooved drum drive plate on a Japanese Murata automatic winding machine.

After the company introduced Murata's fully automatic winding machine from Japan, Zhang Yong set the yarn twisting parameters and electric cleaning parameters suitable for the company's production by reading technical data and practicing repeatedly. When the imported self-winding machine parts were damaged, they were sent to the agent for repair in the past, which not only cost tens of thousands of yuan each time, but also delayed production time. He studied hard and repaired it himself, saving the company about 600,000 yuan each year.

"Before the Mid-Autumn Festival, the workers reported that the appearance quality of the T80 twisted wire ends was not very good, and if not handled in time, it would affect the product quality." Zhang Yong said that he immediately went on the machine to check and found the problem was a bit complicated, so he and the team started the research mode.

In 1996, Zhang Yong graduated from Hai'an Technical School with a major in electromechanical engineering and joined Double Great Textile. He devoted himself to the technical transformation and innovation of textile equipment. From an ordinary electrician, he became a specialist in the national textile industry and a skilled technician in many fields such as electrical engineering, cotton spinning, automation and control.

Over the past 10 years, Zhang Yong has used his spare time to teach himself cotton spinning expertise, electronic automatic control technology, and foreign languages, and has achieved independent maintenance of the company's imported equipment.

Once, an Italian automatic winding machine in the thread-making workshop suddenly stopped. After receiving the repair call, Zhang Yong rushed to the scene with a toolkit. He carefully checked each component of the machine to see if there was a problem with the computer program, but after re-downloading it, it still didn't work. After repeated inspections, he found that there was a problem with the rectifier inverter unit. After replacing the IGBT and optocoupler, the fault was immediately solved.

Learn by doing, and do by learning. Zhang Yong pursues electrical technology diligently and studies it hard. "To make the equipment listen to you, you must understand what the equipment says," this is what Zhang Yong often says. Through years of exploration and innovation, he has achieved autonomy in the maintenance and repair of electrical control components, which not only saves maintenance costs, but also improves the efficiency of equipment operation, creating more than 1.5 million yuan of value for the company every year. In 2014, Zhang Yong won the title of National Technical Expert in the Textile Industry. In 2015, he was named the gold medal worker of Double Great and was awarded 60,000 yuan in technical shares.

In 2016, the company established a Skill Master Studio, with Zhang Yong as the director, taking on the important tasks of skill talent training, technical exchange, project innovation, etc. At present, the studio has 15 members, all of whom are technical experts in various work sections. They have participated in the innovation and research of 8 technical transformation projects, creating more than 10 million yuan of benefits for the company.

His skills resonate with the development of the company, he said, and his growth process is a reflection of the company's emphasis on the cultivation of high-skilled talents. The company has implemented a dry stock reward system for technical personnel, established a level treatment docking system for professional and technical backbones and administrative cadres, carried out a gold medal worker, chief technician, and Double Great craftsman selection mechanism, and implemented a skill allowance system, a master-apprentice system, and a generalist subsidy system for operators. Despite the impact of the epidemic this year, the employee training school where Zhang Yong is a lecturer has not stopped. Through online and offline, classroom and computer methods, it has jointly organized professional training courses such as cotton spinning, modern textiles, and mechatronics with Jiangnan University, Jiangsu Institute of Technology and other colleges and universities, and 94 young employees have participated in part-time learning.

English

English русский

русский Español

Español